Editor: Power Usage with Reaction Wheels

Description

By default, reaction wheels will not have power usage. An EPS (Electrical Power System) bus must be configured with a lookup table for a reaction wheel array to be connected properly. This guide will explain how to connect up the reaction wheels with the power bus for accurate power usage models and flight software connection. This tutorial assumes knowledge from the Editor: Reaction Wheel Power Software guide and an example of this software functioning must be done before attempting the steps shown here.

Configuring the Power Bus

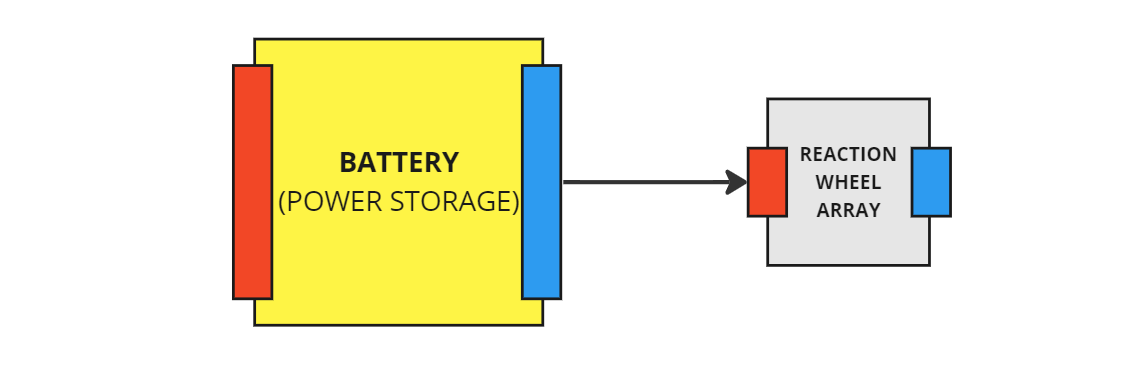

For this system to work, a power bus must be connected with a battery and a reaction wheel connected in series in a basic circuit. This circuit is the minimum requirement and additional switches, loads and sources can be added to the circuitry if required - this will not be covered by this tutorial however.

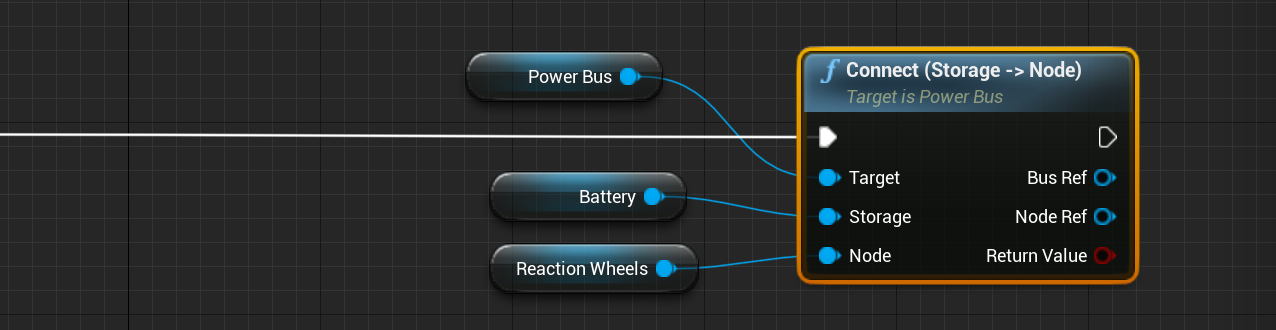

In Blueprints, this can be done using the Connect (Storage -> Node) function, which will attach a battery and a reaction wheel, connecting them in series.

Note

Other power components, such as current limiters, switches or loads, can be connected in series both before and after the connection between the battery and the reaction wheels. As long as the reaction wheels are connected to the battery, then this process will work correctly.

Adding the Motor Power Model

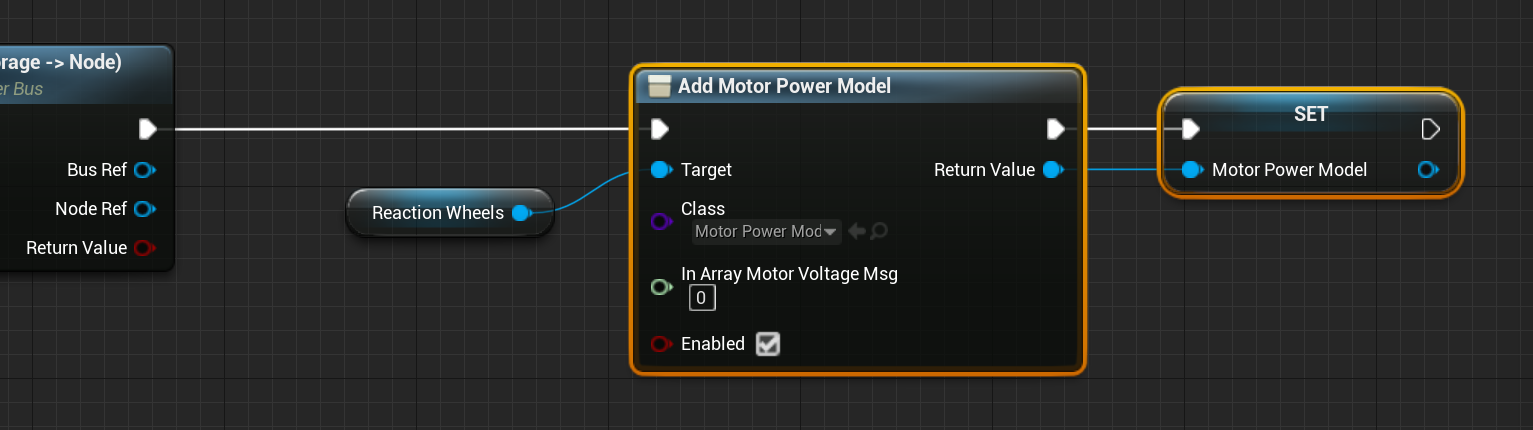

A motor power model is a model that enables the reaction wheel array to draw power from the power bus based on the array voltage messages that are created by the flight software. This can be added using the Add Component by Class node and selecting Motor Power Model in the class dropdown. The reaction wheels are the target of the model.

The In_ArrayMotorVoltageMsg specifies the voltage input from the reaction wheels, calculated by the flight software defined in the previous tutorial. This can either be connected on the constructed or later. In this case, the value will be kept as undefined at first and will be connected after using the Set In Message function on the model.

Adding Lookup Tables

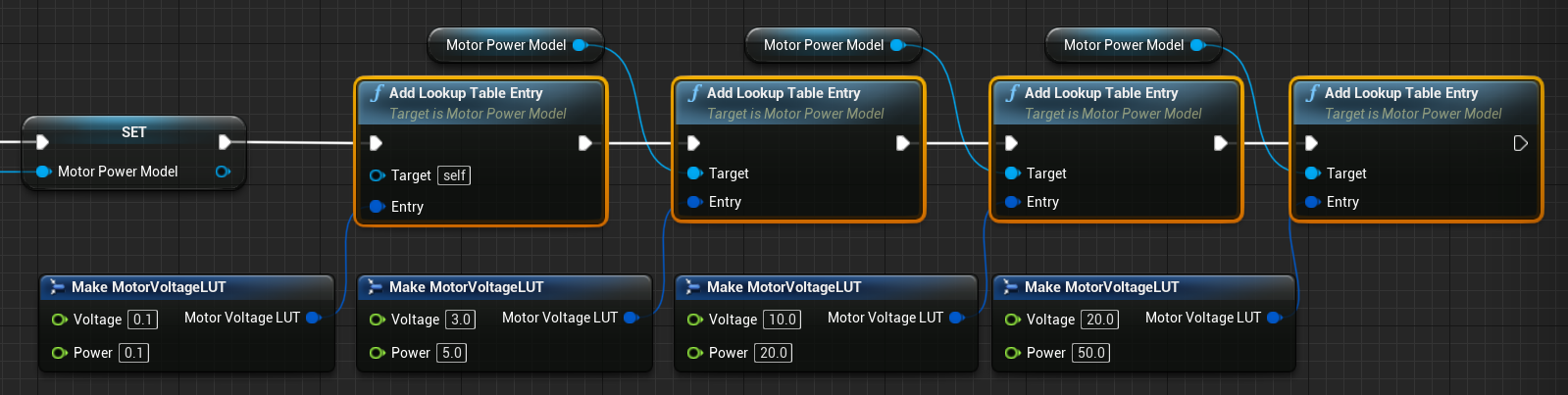

By default, the motor power model will not be able to associate any voltage with power. A lookup table is required to be loaded to convert voltage inputs into power draws. The Add Lookup Table Entry allows for multiple lookup tables, in the form of Motor Voltage LUT, to be added to the power model. These correlate voltage to power levels and a linear curve is created between the points provided when calculating the power based on a voltage sum that is in between two points. It is important to note that the curve data from the last two points extends past the last point when calculating the power draw for large voltages.

Note

Ensure that for each entry added, the voltage increases in value.

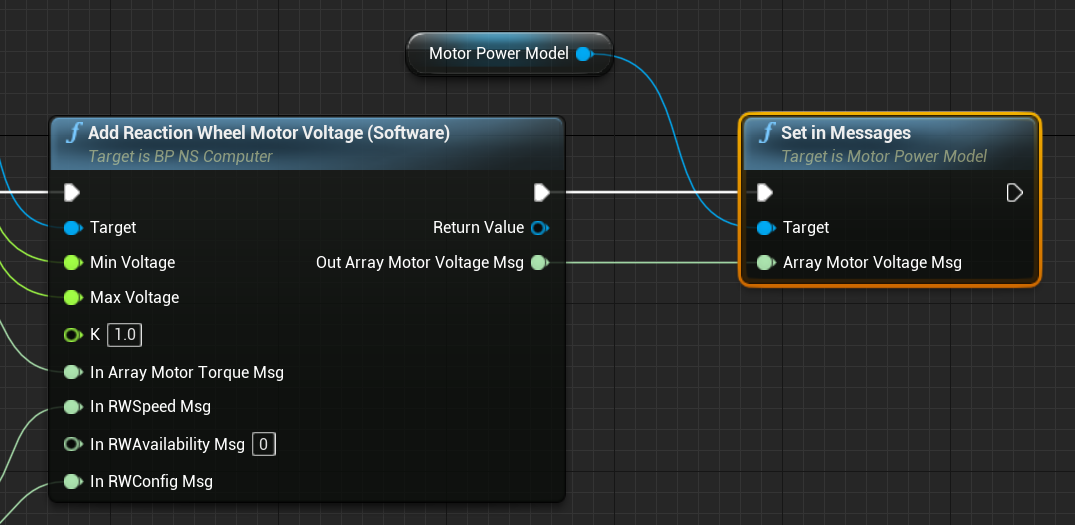

Connecting the Voltage Messages

The final stage of the power system is to connect the input message for the motor power model with an output message from the flight software chain. This comes from the Reaction Wheel Motor Voltage software node and is named Out_ArrayMotorVoltageMsg. Setting the input message of the power model will connect the messages correctly.

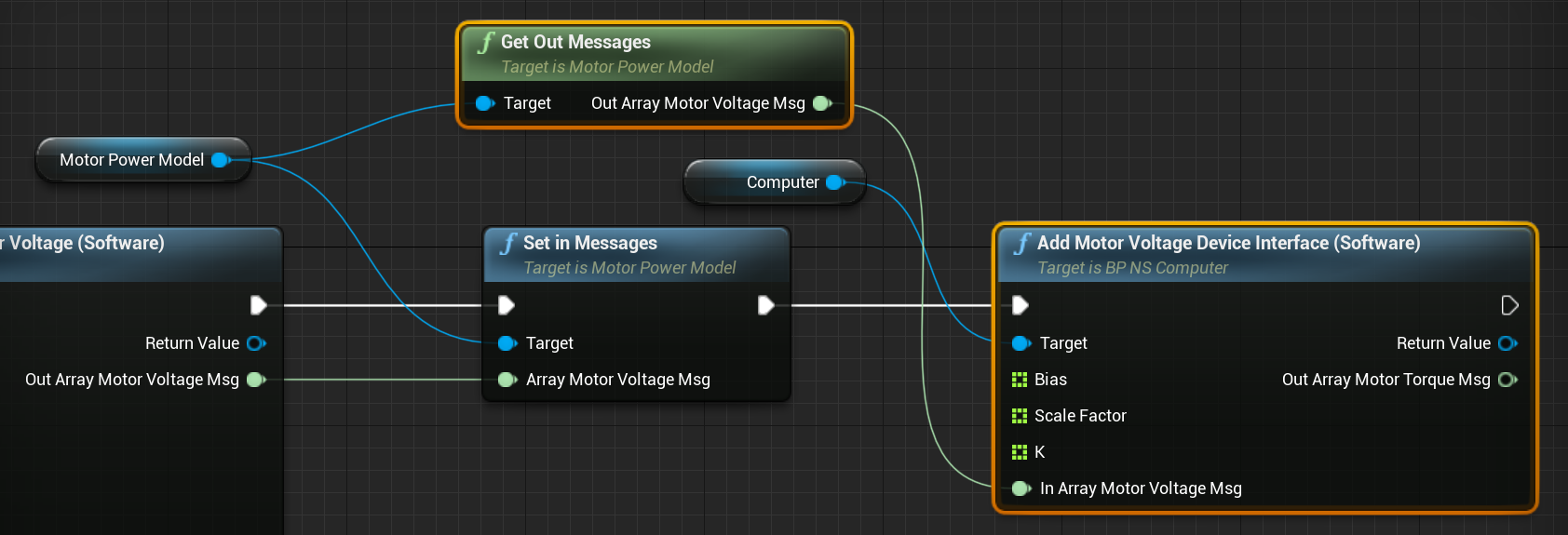

The output Out_ArrayMotorVoltageMsg from the power node can then be connected to the Motor Voltage Device Interface software when constructing the node (or setting the input messages after).

Note

Both the input and output messages for the motor power model are of the same type. The message outputted will be zeroed if the power bus has no more power and will ensure that the reaction wheels do not move if this occurs. Additionally, if a voltage or current limit is applied to the power network, then the final voltages will be scaled down appropriately to meet this cap.

Demo Result

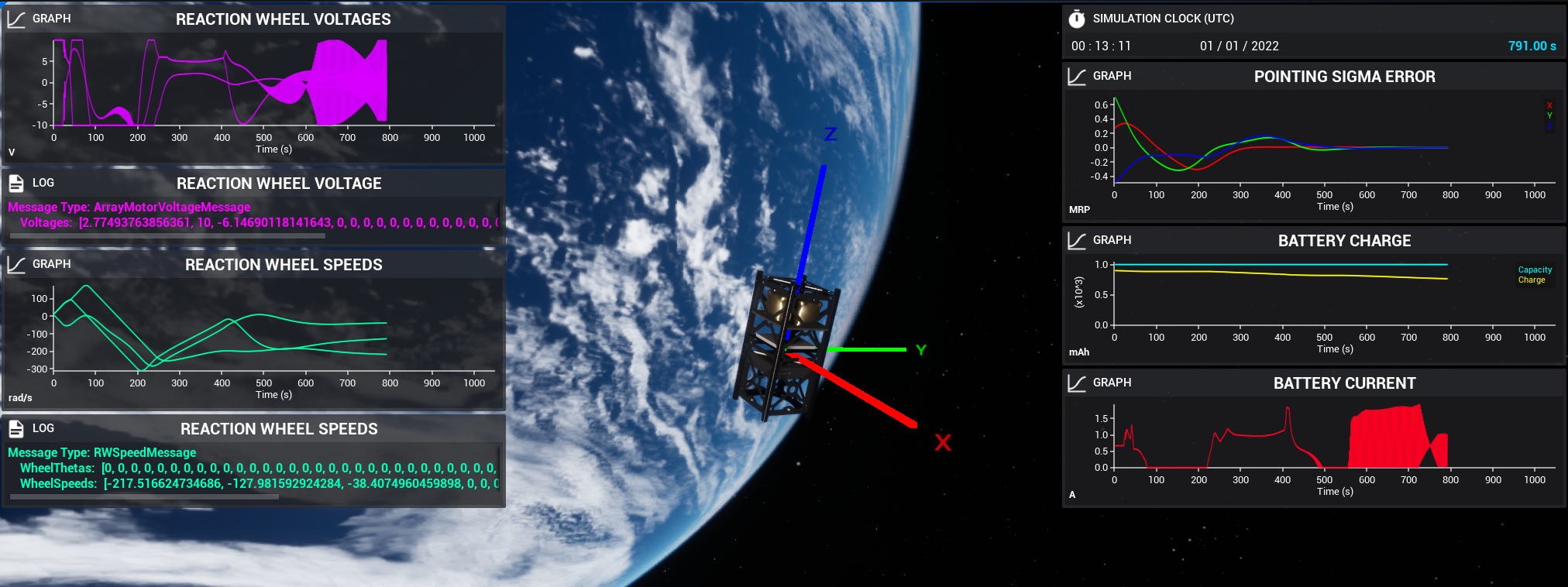

When running the Power/Demo_AttitudeFeedbackRWPower demo, which demonstrates the reaction wheel power software and EPS bus, when the spacecraft reaches the expected target attitude, the voltage will appear to fluctuate.

Note

This is an expected effect, as any tiny changes to the attitude target frame will result in an overcompensating voltage for each wheel. This can be adjusted with some logic on the minimum and maximum wheel torques allowed on the reaction wheels or by tuning the PID controls of the feedback loop.